Roar Solutions for Dummies

( Area 0, 1, or 2). This variant will certainly likewise affect the resourcing needs for job preparation. When Great deals are specified, you can establish sampling plans based on the sample dimension of each Lot, which refers to the variety of random devices products to be evaluated. To identify the needed example size, two aspects need to be evaluated: the size of the Lot and the category of examination, which indicates the degree of initiative that should be applied( decreased, normal, or increased )to the evaluation of the Great deal. By integrating the category of evaluation with the Great deal dimension, you can then develop the ideal being rejected requirements for a sample, suggesting the allowed variety of malfunctioning products located within that sample. For more details on this process, please refer to the Power Institute Guidelines. The IEC 60079 typical advises that the maximum interval between evaluations must not go beyond 3 years. EEHA assessments will certainly likewise be conducted beyond RBI campaigns as component of arranged upkeep and devices overhauls or repairs. These inspections can be attributed toward the RBI example dimensions within the affected Whole lots. EEHA examinations are conducted to identify mistakes in electric tools. A weighted racking up system is necessary, as a single item of devices may have numerous faults, each with differing levels of ignition threat. If the consolidated rating of both evaluations is less than two times the fault score, the Whole lot is regarded acceptable. If the Whole lot is still considered unacceptable, it has to undergo a complete assessment or justification, which might set off stricter inspection procedures. Accepted Whole lot: The causes of any mistakes are determined. If a typical failing mode is discovered, added tools may need examination and fixing. Mistakes are identified by severity( Security, Stability, Housekeeping ), making sure that immediate concerns are assessed and dealt with immediately to minimize any type of influence on safety and security or operations. The EEHA data source should track and record the lifecycle of faults together with the rehabilitative actions taken. Applying a robust Risk-Based Inspection( RBI )strategy is essential for guaranteeing compliance and security in managing Electrical Equipment in Hazardous Areas( EEHA). Automated Mistake Rating and Lifecycle Management: Effortlessly handle mistakes and track their lifecycle to boost examination precision. The intro of this support for risk-based inspection further strengthens Inspectivity's setting as a best-in-class option for regulative compliance, along with for any asset-centric inspection use instance. If you want finding out more, we welcome you to ask for a demo and find exactly how our option can change your EEHA administration processes.

With over 10 years of consolidated Ex-spouse experience (IECEx/ATEX, EEHA), Saipex started to advertise the value of competence of all employees included in the Hazardous Location area in 2019. In 2021, our collaboration with IndEx and Technology Skill International (TSI) marked a milestone in the Saipex roadway to continue Ex lover renovation.

The Buzz on Roar Solutions

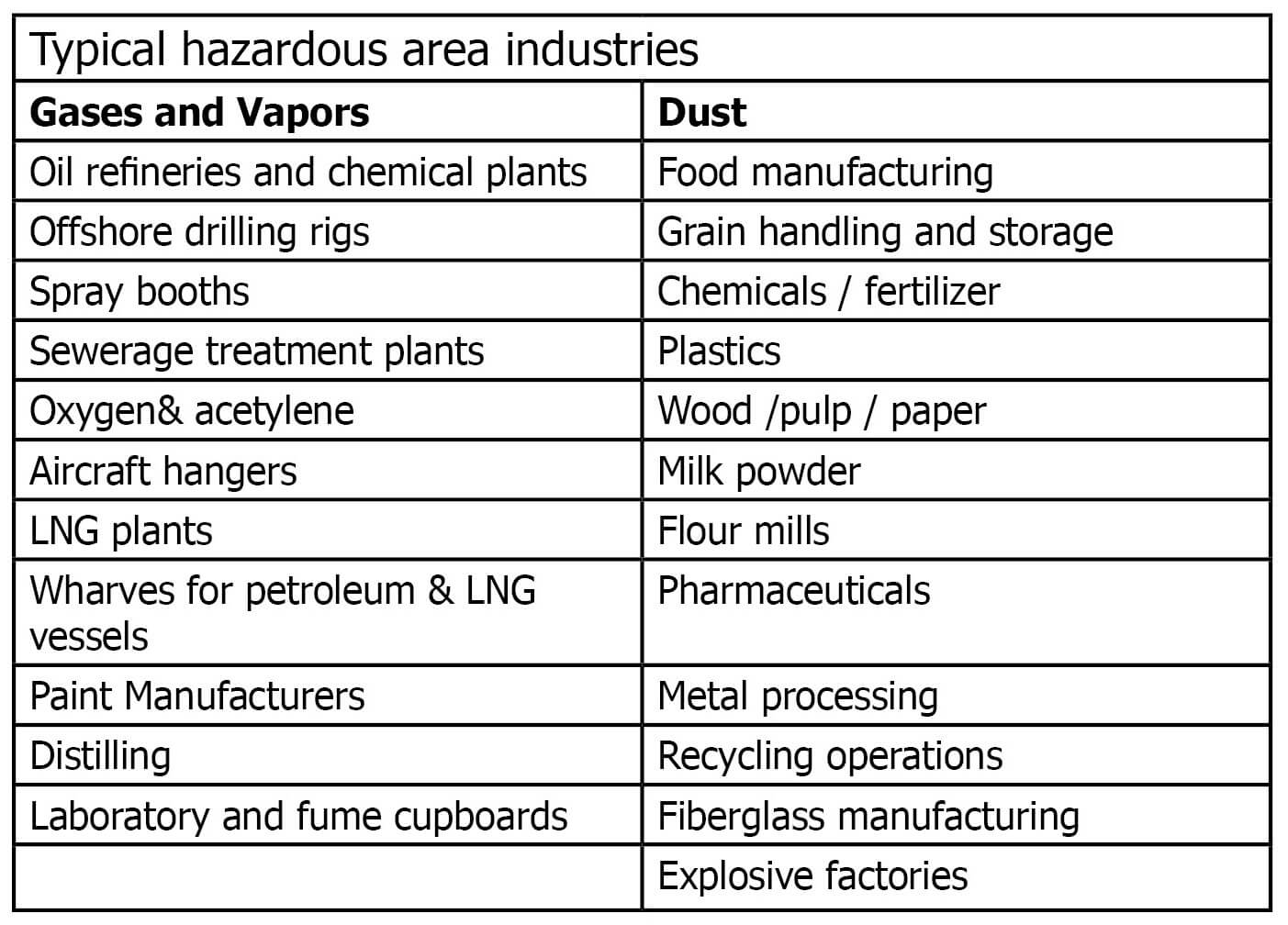

In terms of explosive danger, a hazardous location is an environment in which an eruptive ambience is present (or might be anticipated to be present) in amounts that call for unique preventative measures for the building and construction, installation and use equipment. In this post we explore the challenges faced in the work environment, the risk control steps, and the called for expertises to work safely.

These substances can, in specific problems, form eruptive environments and these can have major and heartbreaking effects. Most of us are acquainted with the fire triangular remove any kind of one of the three aspects and the fire can not take place, but what does this mean in the context of hazardous areas?

This is after that validated through inspection and screening and is maintained throughout the life of the installation by using the appropriate upkeep methods, supplemented by routine inspection. When all these actions are taken, they ought to likewise be recorded. The confirmation file includes info such as the hazardous location category drawing, suppliers' documentation, equipment qualification, design illustrations and calculations, evaluation documents, and documents of an individual's expertise and proceeding professional advancement (CPD), such as using ECA's eCOMS software application.

The 2-Minute Rule for Roar Solutions

It is imperative that trainees comprehend and have a comprehensive expertise regarding just what makes up a harmful area. The trainee must additionally understand why training is essential prior to trying to take on work or defining equipment into an unsafe location. These locations are additionally called identified places and are specified as areas which have a high possibility of a surge due to the fact that of the feasible presence of combustible gases, vapors, dusts etc.

Industries that include dangerous areas are currently demanding that electrical workers that are defining or operating in these locations must have a harmful location credentials that regards them skilled. Jobs in these industries are extremely satisfying so you need to be prepared. To meet this demand for the industry, nationally recognised training in Certification IV in Harmful location Electric and EEHA training on the advancement of proficient experts.

The Single Strategy To Use For Roar Solutions

Tech Skills Australia is a Registered Training Company offering you with one of the most budget friendly and quickest method obtaining your certification - eeha training. Our trainers are market qualified and have several years of procedure experience. Our programs have helped numerous individuals from company managers to daily workers in acquiring a solid hang on this not so complicated but high threat training

The training additionally includes identifying the dangerous areas, resources of explosion and the browse this site properties of unsafe products together with the obligations and functions of all parties, regulations, systems, criteria and practice codes attached to harmful areas. We give instrumentation and harmful location options that are in compliance to newest AS/NZS and international sector requirements.

Comments on “Fascination About Roar Solutions”